Something updated (05/07/2012)

I have to much cut off material piling up in the shop, from other projects. So I needed a material rack now. I also have to find what material I have easily. I have a very compact shop 20' x 20'.

Material

Rack (2011)

Something updated (05/07/2012)

I have to much cut off material piling up in the shop, from other projects.

So I needed a material rack now. I also have to find what material I have easily.

I have a very compact shop 20' x 20'.

Finished heavy frame (1 1/2 angle iron .250 wall), ready to tack

up sheet metal rack on back side.

Wife finishing up welding sheet metal rack base.

I use spool guns exclusive. I switch to internal C02 and 110v, when real portable

welding is needed. At the welding table it's only C25. When welding aluminum, I

switch to another spool gun, loaded with 4043 wire and argon gas. Works great. Great welder Miller

Passport Plus 45 lbs 110v/220v, spool gun ready.

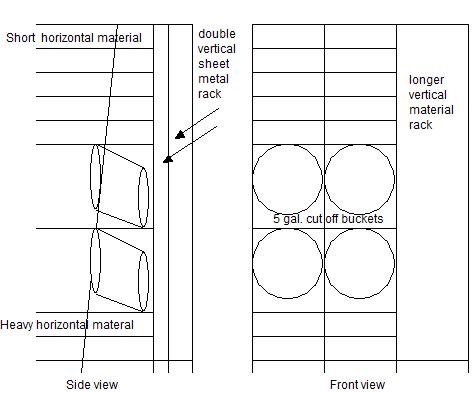

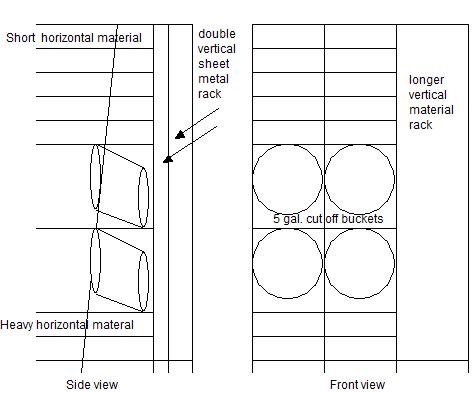

Here's some work on the bottom. Got the cross shelf braces in and runners for

sliding sheet metal in the back area of rack. You can see a single cross brace

just off this end. That's where the vertical 5 to 6' stuff goes.

Here is the beginning of shelving, on the horizontal storage side, 2' to 4' stuff. That means I should have very little left over material on projects, good luck. That's why shelves very narrow. So if I have a lot of something I shouldn't be buying more, such a plan. Like I said, I want it to be able to be picked up with a forks on tractor front loader. The 4 buckets are built from rings, they will hold really short cut offs.

Got it part way done 7 shelves. Sheet metal stored in the back. The material in the rack is only what I could grab from arm reach. Theirs much more. Got to add some horizontal bars in the vertical rack area.